benterryfarm

Member

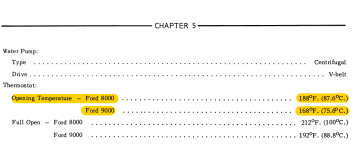

I have a Ford 8000 and 9700. The 8000 recently had oil (most likely diesel) coming out of the exhaust manifold. I'm familiar with wet stack, as it would always happen on my Agco 5670 while running a hydraulic wood splitter for an extended time in the winter. I'm assuming that is what is happening with my 8000 now but not 100% certain. First question is what thermostat temperature did these tractors have from the factory? CNH has listed a 168 F option as well as a 188 F (also listed as 192 F on some websites). The 168 seems ridiculously low, which leads to my second question, if indeed my tractor has that thermostat how much would switching to a 192 thermostat help my issue with oil coming out of the manifold?