Tractorcedric

Member

- Location

- Garland. Utah

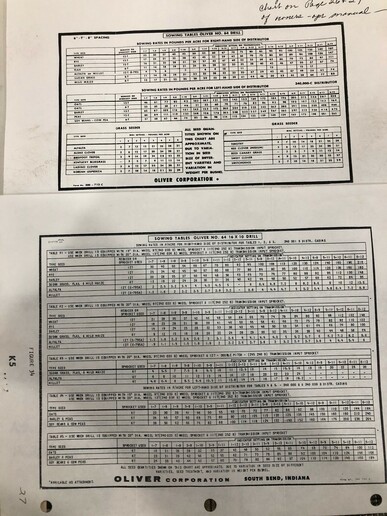

Oliver 64 drill settings? It has a chart in the front lid. But I do not have an operators manual. I would like to know how to set it for a three way forage mix to be cut for hay. Seed supplier said to put on 40 lbs per acre. The chart has settings for wheat, barley and oats. But not for all three as a mix. Also not sure how the distributor works. Chart references a 12 tooth on the left side, but mine has a 13 tooth gear on the left side at the top. Anyone have a manual they could share pictures of till I can get a manual. Has anyone planted a three way with one of these drills. What are the covers for in the bottom of the large seed box? Thanks for any help?