jon f mn

Well-known Member

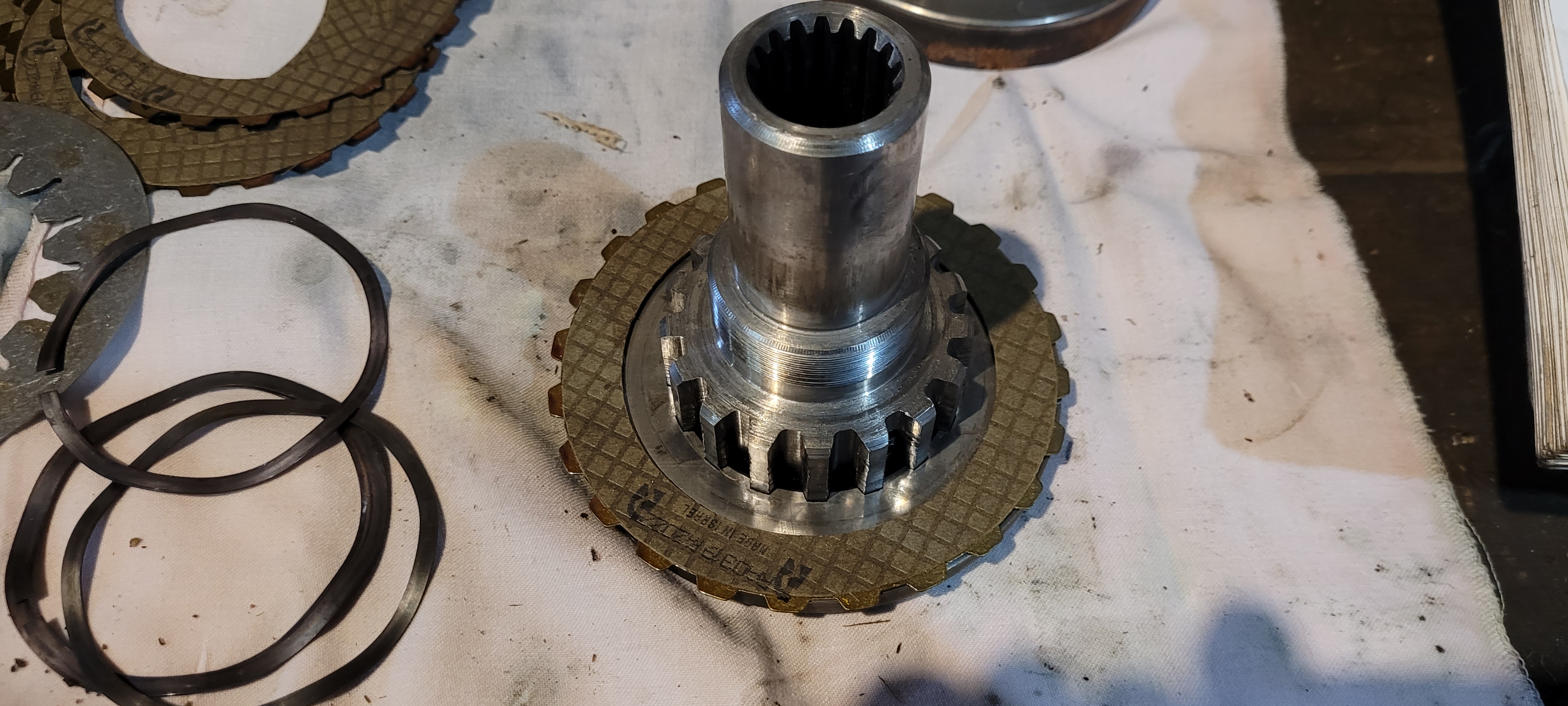

Made some progress on getting the 830 back together yesterday. Started with the pto clutch because I've done them before and they are easy. Just clean the up and stack the parts in proper order.

First a driven disc, then a spring, then a drive disc. Then just repeat til you get them all in.

I did find out that the pin that holds the adjustment will fall out with the spring and fall between the boards on my bench and down into the "stuff" underneath. Took some digging to find them. Lol

All done and ready go back in.

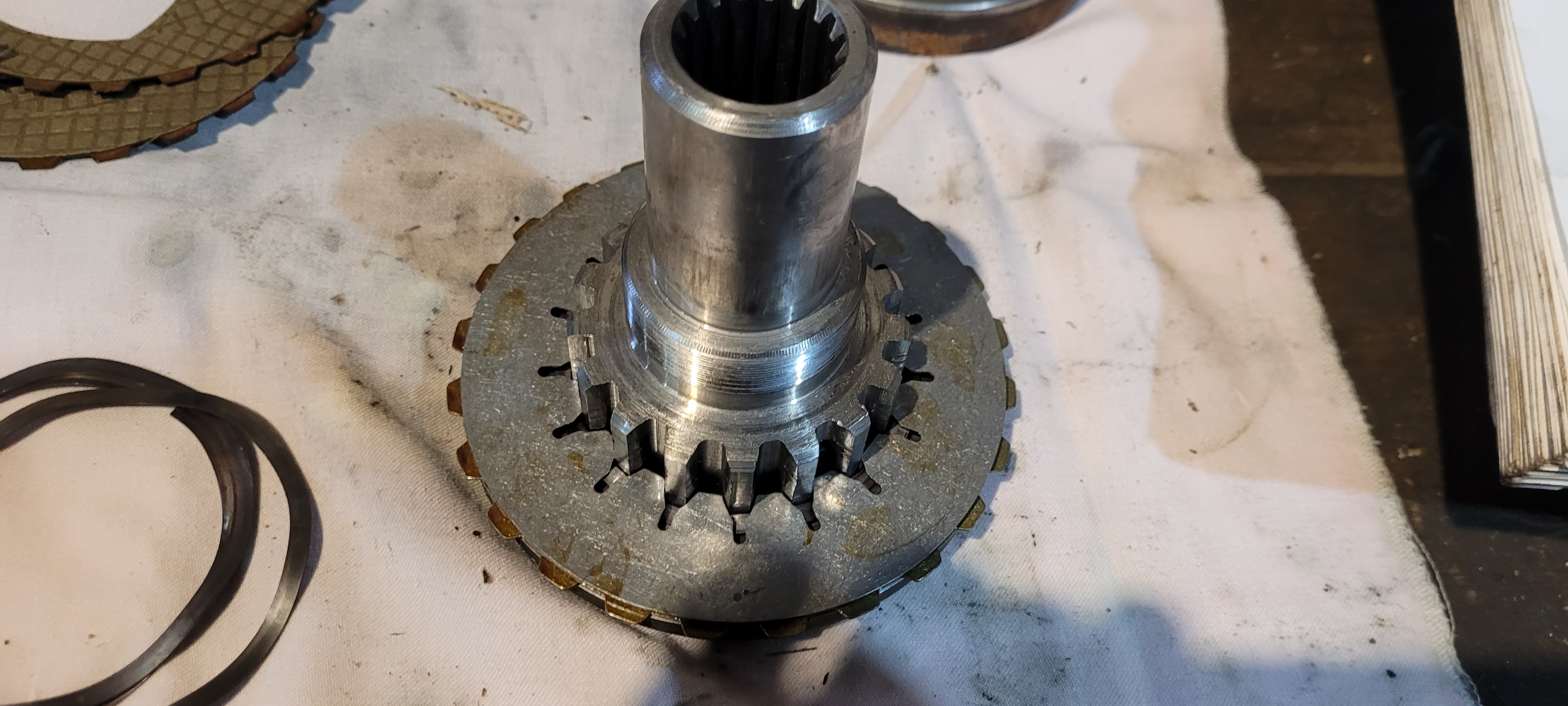

Then the com, that was a bit more difficult. I intended to take pics along the way, but got so distracted i completely forgot til was done. Worst was the snap ring that holds the bearing on the main shaft. The gap was so wide even my big snap ring plier wouldn't take it off. Fought that for a couple hours and used my entire collection of naughty words. Also had trouble getting the large seal rings I'm, they really didn't want to stay in the slot. Cleaning took some time too, all the slots and holes were full of gunk. Took some time to clean all that out. I prelubed the bearings with oil and all the seal rings and o-rings with assembly lube to help with lube on start up. Here it is all done.

Still have to replace the front trany seal, rear main seal on the engine, rebuild the 3pt valve, and seals where the injection pump mounts. I'll also have to build a tool for lifting the com into place, not doing that by hand like i took it out. Lol. Hope to get all that done next weekend.

First a driven disc, then a spring, then a drive disc. Then just repeat til you get them all in.

I did find out that the pin that holds the adjustment will fall out with the spring and fall between the boards on my bench and down into the "stuff" underneath. Took some digging to find them. Lol

All done and ready go back in.

Then the com, that was a bit more difficult. I intended to take pics along the way, but got so distracted i completely forgot til was done. Worst was the snap ring that holds the bearing on the main shaft. The gap was so wide even my big snap ring plier wouldn't take it off. Fought that for a couple hours and used my entire collection of naughty words. Also had trouble getting the large seal rings I'm, they really didn't want to stay in the slot. Cleaning took some time too, all the slots and holes were full of gunk. Took some time to clean all that out. I prelubed the bearings with oil and all the seal rings and o-rings with assembly lube to help with lube on start up. Here it is all done.

Still have to replace the front trany seal, rear main seal on the engine, rebuild the 3pt valve, and seals where the injection pump mounts. I'll also have to build a tool for lifting the com into place, not doing that by hand like i took it out. Lol. Hope to get all that done next weekend.