Family history stories suggest my grandfather may have put up one of the first Harvestore silos. Somewhere I remember reading that there were 3 initial demo Harvestores and one was in Jefferson county, WI. What I do know is that the first silo on his farm was replaced due to glass lined failure, sometime in the 50's. The silo was filled the last time by my grandfather in 1969. I rented the farm in 1979 and fed that hay silage to cattle. I refurbished the silo and filled it with high moisture corn. I remember filling that silo with an Allis WD, pulling the wagon, and an Allis WD 45 on the blower. Since the WD came out in 48, and the WD45 came out in 53, questions remain on what year that silo was put up. An aerial 1953 farm photograph shows the silo and the self unloading wagons my father had built. My grandfather's farm life saw the transition from horse to tractor. Oh how I wish I had been more interested in history 50 years ago and asked my granfather more questions. I would love to know how they filled the wood stave and HUGE mortar and stone silos with horses.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter apranke

- Start date

showcrop

Well-known Member

I remember my uncle filling his wood stave silo in the early sixties with a belt driven blower powered by one of his Fords. If he had the silo before the tractor he could have rented one for harvest. Before he got his third tractor our neighbor rented one for a few weeks.

Part Time Pete

Well-known Member

- Location

- Leatherstocking Region NY

A lot of them went up here in central NY in the 70's. Mostly 20x70's for haylage and I believe 20x40' for high moisture corn. The father of one of the guys I

worked for was on the Agway board of directors, so they had a seal-store (I think they were affiliated with Agway)

They all sit empty or have been taken down now

worked for was on the Agway board of directors, so they had a seal-store (I think they were affiliated with Agway)

They all sit empty or have been taken down now

crooked rows

Member

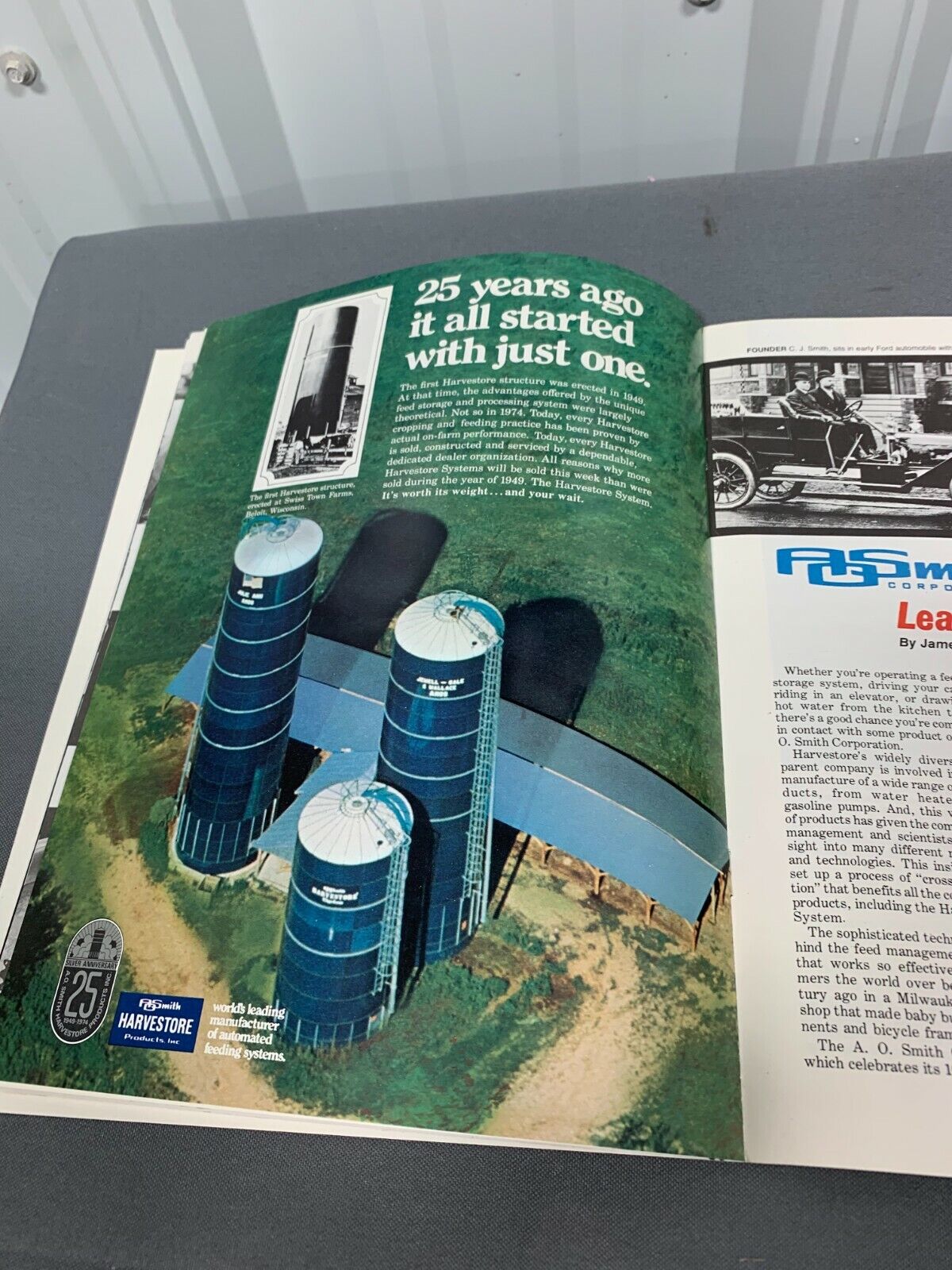

I found a source that says the first Harvestores were introduced in 1949. I would say that not too many were built in my part of Michigan until the 1960's and 1970's .

Bruce from Can.

Well-known Member

- Location

- Woodville, Ontario, Canada

Silage was put into silos long before the modern farm

tractor and forage harvesters came along. Corn was

cut with a corn binder making sheaves. The sheaves

of corn loaded by hand on to wagons were hauled to

the silo. At the base of the silo was a cutting box

which could be powered by a steam tractor or a

stationary gas or Kerosene engine. Sheaves of corn

were fed by hand into the cutting box and the cutting

box both chopped and blew the corn silage ou a pipe

into the silo. Your WD45 was a very advanced method

of doing corn silage compared to hauling sheaves

with horses

tractor and forage harvesters came along. Corn was

cut with a corn binder making sheaves. The sheaves

of corn loaded by hand on to wagons were hauled to

the silo. At the base of the silo was a cutting box

which could be powered by a steam tractor or a

stationary gas or Kerosene engine. Sheaves of corn

were fed by hand into the cutting box and the cutting

box both chopped and blew the corn silage ou a pipe

into the silo. Your WD45 was a very advanced method

of doing corn silage compared to hauling sheaves

with horses

My uncle was a early Harvestore dealer. Early Harvestore silos were 17 foot in diameter. Some time in the 1960's 17 foot diameter silo unloaders were discontinued. If a new unloader was wanted a 20 foot Goliath unloader had to be purchased and cut down to size. Very expensive.

My uncle had 4 on his farm and we had 4 17 footers.

And yes, if a silo unloader was broken and could not be pulled out to fix my uncle would burrow into the silo and fix it.

My uncle had 4 on his farm and we had 4 17 footers.

And yes, if a silo unloader was broken and could not be pulled out to fix my uncle would burrow into the silo and fix it.

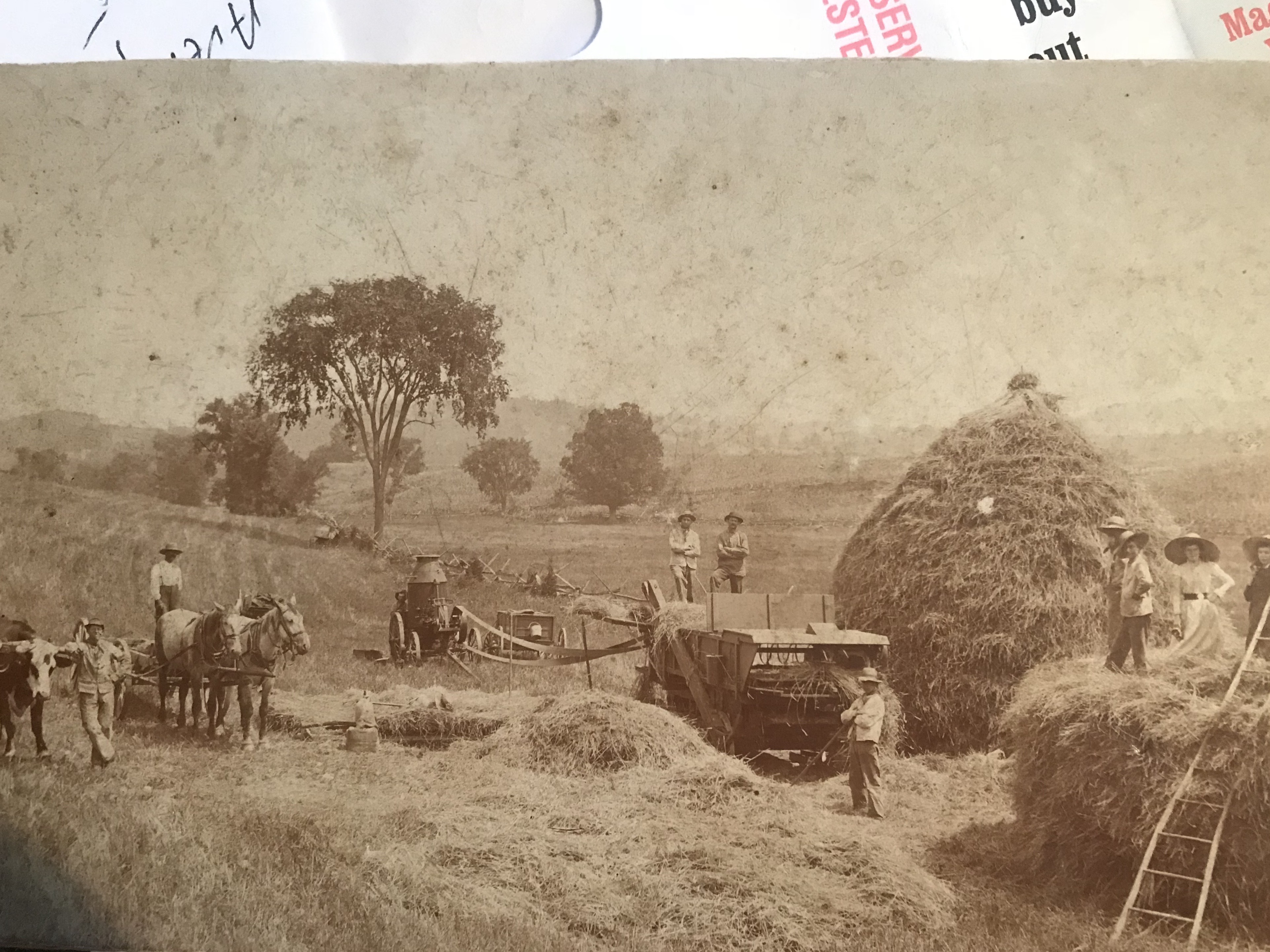

My great grandfather bought the farm sometime in the late 1890's. I have a photo from 1917 with those sheaves of corn on the wagon. Behind the wagon is the wood stave silo and the monster stone and mortar silo. Sadly, there is no equipment visible to show how the corn was processed or moved into the silos.(quoted from post at 06:23:46 07/27/23) Silage was put into silos long before the modern farm

tractor and forage harvesters came along. Corn was

cut with a corn binder making sheaves. The sheaves

of corn loaded by hand on to wagons were hauled to

the silo. At the base of the silo was a cutting box

which could be powered by a steam tractor or a

stationary gas or Kerosene engine. Sheaves of corn

were fed by hand into the cutting box and the cutting

box both chopped and blew the corn silage ou a pipe

into the silo. Your WD45 was a very advanced method

of doing corn silage compared to hauling sheaves

with horses

This thread has pique my interest in the heavy iron/steel silo still sitting on our farm. Red paint, bolted seams and about 15 foot in diameter and about 45 foot high. Probably had a wood top which is long gone. My guess it is 80 to 100 years old Don't know of another in the area. Got to do some research into local history.

farmerjohn

Well-known Member

My great grandfather erected a wood stave silo on the farm in 1917, it was 10 x 27, the manufacturer was Indiana Silo Co. I still have the hoop

wrench with the name embossed on it. It was warranted to last 25 years, we pulled it down in 1992, used the staves for flooring in a shed.

They bought a Papec silage cutter to fill it, I can remember it still being used when I was a kid in the 1960s, we still have it in the barn.

wrench with the name embossed on it. It was warranted to last 25 years, we pulled it down in 1992, used the staves for flooring in a shed.

They bought a Papec silage cutter to fill it, I can remember it still being used when I was a kid in the 1960s, we still have it in the barn.

In the days before tractors. Our first silo was erected in 1911. Well before tractors came into use. The powered equipment at our farm was powered by one cylinder

engines including a milking machine in 1914. Hinman from upstate New York. Steam engines were the big power of the day. Corn was cut either by hand with a corn knife

and then bundled and tied with a cornstalk or a binder was used which cost more money but went a good deal faster. A corn binder pulled by two horses was the

standard setup in my day. Although, there were plenty of corn knives around. I remember when, in 1951, a tornado went thru in September and blew down about 15 acres of

corn. Flattened it. That following weekend about 30 or 40 farmers showed up with their corn knives and cut all that corn in very little time. I drove over with a

flatbed wagon and joined others picking up the corn and driving up to the silo filler. We had a quite a lineup. Filled a 12 X 40 that day. So, after cutting and

bundling the corn it was either loaded on a flat bed wagon and hauled up to the silo filler or was shocked up in the field to be broken apart later and the husked ears

loaded on a wagon and hauled to the corn crib. The stalks were then hauled in and run thru a stalk cutter to be used for bedding. The silo fillers, many of them,

employed an elevator rather than a blower if powered by a stationary engine although blowers were used on some for shorter silos or bigger engines were used. A lot of

hard work. Those corn bundles were made up of wet corn and they were heavy. To get them up on a big load we used 3 tined pitchforks. Horses were all around. No mules, ever. Every farm

had them until right after World War II. (The Big One) when tractors anf fuel became more available. We needed three teams of big horses to keep our farm going until the first

Fordson showed up. Then we dropped to two teams. When the WC Allis Chalmers came on line in 1936 our need for horses dropped to one team. Then, in 1949, a new WD in

addition to the WC and no more horses. There went the oat market. (;>))

engines including a milking machine in 1914. Hinman from upstate New York. Steam engines were the big power of the day. Corn was cut either by hand with a corn knife

and then bundled and tied with a cornstalk or a binder was used which cost more money but went a good deal faster. A corn binder pulled by two horses was the

standard setup in my day. Although, there were plenty of corn knives around. I remember when, in 1951, a tornado went thru in September and blew down about 15 acres of

corn. Flattened it. That following weekend about 30 or 40 farmers showed up with their corn knives and cut all that corn in very little time. I drove over with a

flatbed wagon and joined others picking up the corn and driving up to the silo filler. We had a quite a lineup. Filled a 12 X 40 that day. So, after cutting and

bundling the corn it was either loaded on a flat bed wagon and hauled up to the silo filler or was shocked up in the field to be broken apart later and the husked ears

loaded on a wagon and hauled to the corn crib. The stalks were then hauled in and run thru a stalk cutter to be used for bedding. The silo fillers, many of them,

employed an elevator rather than a blower if powered by a stationary engine although blowers were used on some for shorter silos or bigger engines were used. A lot of

hard work. Those corn bundles were made up of wet corn and they were heavy. To get them up on a big load we used 3 tined pitchforks. Horses were all around. No mules, ever. Every farm

had them until right after World War II. (The Big One) when tractors anf fuel became more available. We needed three teams of big horses to keep our farm going until the first

Fordson showed up. Then we dropped to two teams. When the WC Allis Chalmers came on line in 1936 our need for horses dropped to one team. Then, in 1949, a new WD in

addition to the WC and no more horses. There went the oat market. (;>))

Highwayman

Member

Our farm had a wood silo that I only remember being filled once before it was taken down to make way for an our second harvestore. We used a belt driven table blower powered.by a Farmall H. Then pto blower when the first 60’ harvestore came.

I have a picture of a portable steam engine running a thresher that probably could have been used for a silage cutter as well.

My dad loved his harvestores we had 7 of them. Plus a slurry store.

I have a picture of a portable steam engine running a thresher that probably could have been used for a silage cutter as well.

My dad loved his harvestores we had 7 of them. Plus a slurry store.

Absent Minded Farmer

Well-known Member

- Location

- Gehl Country, Wis.

That looks like a Westinghouse portable steam engine & threshing rig. Have any more info on it?Our farm had a wood silo that I only remember being filled once before it was taken down to make way for an our second harvestore. We used a belt driven table blower powered.by a Farmall H. Then pto blower when the first 60’ harvestore came.

I have a picture of a portable steam engine running a thresher that probably could have been used for a silage cutter as well.

My dad loved his harvestores we had 7 of them. Plus a slurry store. View attachment 834View attachment 833View attachment 835View attachment 836View attachment 836

Mike

Highwayman

Member

No I dont

I know the exact spot those pictures were taken and I’m pretty sure that my grandpa with the team of oxen. I figure it’s around 1920. I wasn’t sure what kind of engine it was until I recently saw some closer pictures and googled a Westinghouse steamer and there it was.

I think this had to be a community effort of farmers working together threshing the neighborhood. I remember a threshing machine parked in a building that we stored hay in. But it was definitely more modern than this one

I know the exact spot those pictures were taken and I’m pretty sure that my grandpa with the team of oxen. I figure it’s around 1920. I wasn’t sure what kind of engine it was until I recently saw some closer pictures and googled a Westinghouse steamer and there it was.

I think this had to be a community effort of farmers working together threshing the neighborhood. I remember a threshing machine parked in a building that we stored hay in. But it was definitely more modern than this one

jwal10

Member

- Location

- Western Oregon

There was a wood stave silo here in Western Oregon, on the farm Dad bought in 1953. In 1954 he had a Mt. Hood concrete silo put up. He used the 26' 2"x6" cedar tongue and groove wood staves as rafters on a lean-to between the hay barn above/milking parlour below and the loafing shed. He filled the hay mow with the same equipment as the silo except the Gehl chopper had a pickup header instead of the 1 row corn head. There was a ramp from the hay mow to the feeder that followed the same angle as the roof line. The wheel barrow had a sheet of 2' wide roofing tin around the front and sides to haul a "big" load of chopped hay. Ran it down the ramp and dumped into the feeder. Any way, he got a silo loader with the farm, along with a 1 row chopper. Both were Gehl, both had LeRoi engines. The silo filler had an apron. The 2 wagons had apron floors that ran the feed to the back. The end gate was hinged on the top and small pegs fit in the chain links. When you started the pto the pegs were pushed back by the chain and the rear door opened. He used a bent tine "fork" to feed the silage onto the apron of the silo filler. Some times a big pile fell off the wagon into the apron and plugged the silo filler. When he sold the dairy cows, he kept using the silo for the beef cows but he bought a new Bear-cat flail chopper, a new Gehl silo filler and a side discharge Gehl silage wagon, new....James

Absent Minded Farmer

Well-known Member

- Location

- Gehl Country, Wis.

The first Harvestore was built on their research farm north of Beloit in '49. It is no longer there, but the farm is. Locally, the property is known as the Swisstown farm. I recall asking about the property years ago, as I thought is was an old creamery or dairy.

Here's a bit more on it from the Beloit Daily News, via the Wisconsin Historical Society site:

"Asymmetrically composed of three gabled bays projecting from a main block (with steeply pitched hip roof) and an octagonal tower at the southwest corner, the J.W. Crist House rises two stories plus attic from a foundation of rock-faced stone. The first and second stories are constructed of brick while the steeply-pitched gables have walls of fish-scale shingles. Gable returns, flared eaves, and a broad frieze ornament the cornice line of the house while each story of the three-story tower is marked by a stone string course. A modified Palladian window in the west gable features Iconic mullions, a molded panel in place of a fanlight and a classical frame with entablature, while other attic windows feature similar frames. The first floor entries and the side bay windows are ornamented with entablatures and doors are framed with pilasters and sidelights. Although the posts and roof of the veranda are now gone, the heavily rusticated stone foundation and walls of the veranda remains. Perhaps the most fanciful ornament is the brick work above the second story of the tower where diagonal rows of raised brick intersect each other to create a diamond pattern. Several additional farm buildings, including an elaborate concrete, brick, and steel dairy barn, built in the mid-20th century as part of the A.O. Smith operation, are located immediately behind the house but do not contribute to the significance of the house and are excluded from nomination. Once called the "Klondike Farmhouse" because its owner/builder had recently returned from the Alaska gold rush of 1896, the J.W. Crist House is architecturally significant as one of the finest Queen Anne houses in the city of Beloit, reflecting the tall proportions, varied massing, and freely interpreted classical detail which are hallmarks of the style. Probably designed by its owner, the Crist house was built as a farmhouse (then on the outskirts of Beloit), and remains today the finest example of a rural Queen Anne house now located in the city of Beloit. This large and imposing Queen Anne house, known as the "Klondike Farm," was built in 1904 by John W. Crist after he successfully mined gold in Alaska. But, if his fortune allowed him to build on a large scale, his background as a skilled carpenter helped him build as well. As a young man, crist worked as a carpenter for the Cunningham Brothers, a local contracting firm, before he moved west to Montana to build bridges for the Northern Pacific Railway. Eventually, Crist went to Alaska where he built a trading post in the Yukon Territory. During the great Klondike gold rush, Crist was reputed to have mined one of the first and richest mines in the territory. In 1901, Crist returned to Beloit, bought the rights to his family's farm, named the operation the "Klondike Farm." and began to build the large brick home which stands today. A strong promoter of rural interest, Crist served on the Rock County Board and other civic panels where he represented agricultural concerns. Throughout this period, the Klondike Farm was noted for its fine flock of sheep and its large herd of beef cattle, and the farm buildings that Crist built were considered among the finest in the county. But in 1914 fire destroyed many of thise buildings and Crist sold the property to W.J. Allen of Beloit who rebuilt the barns. By the early 1940s, the farm was owned by W.C. Heath, an executive with the A.O. Smith Corporation of Milwaukee, who built the present elaborate concrete, brick, and steel dairy barn that stands near the house. Mr. Heath also directed the buliding of one of the finest herds of purebred Brown Swiss cattle on the farm, and gave the place a new name - Swisstown. In 1947, the farm was bought by the A.O. Smith Corporation as a field research center. The corporation used the site for experimenting with such products as Harveststore crop storage units and dairying equipment. Eventually, A.O. Smith sold the property to Lester A. Helgesen of Janesville. Helgesen operated it for a number of years prior to selling it, and in recent years the farm has been partially subdivided. The area is becoming suburbanized, and the site has been annexed to the city."

The address is: 2601 Afton Rd., Beloit, Wi. 53511 if you would like to check it out on Maps.

Here's parts of a brochure I found on the 'net, with a pic of that silo (in B&W):

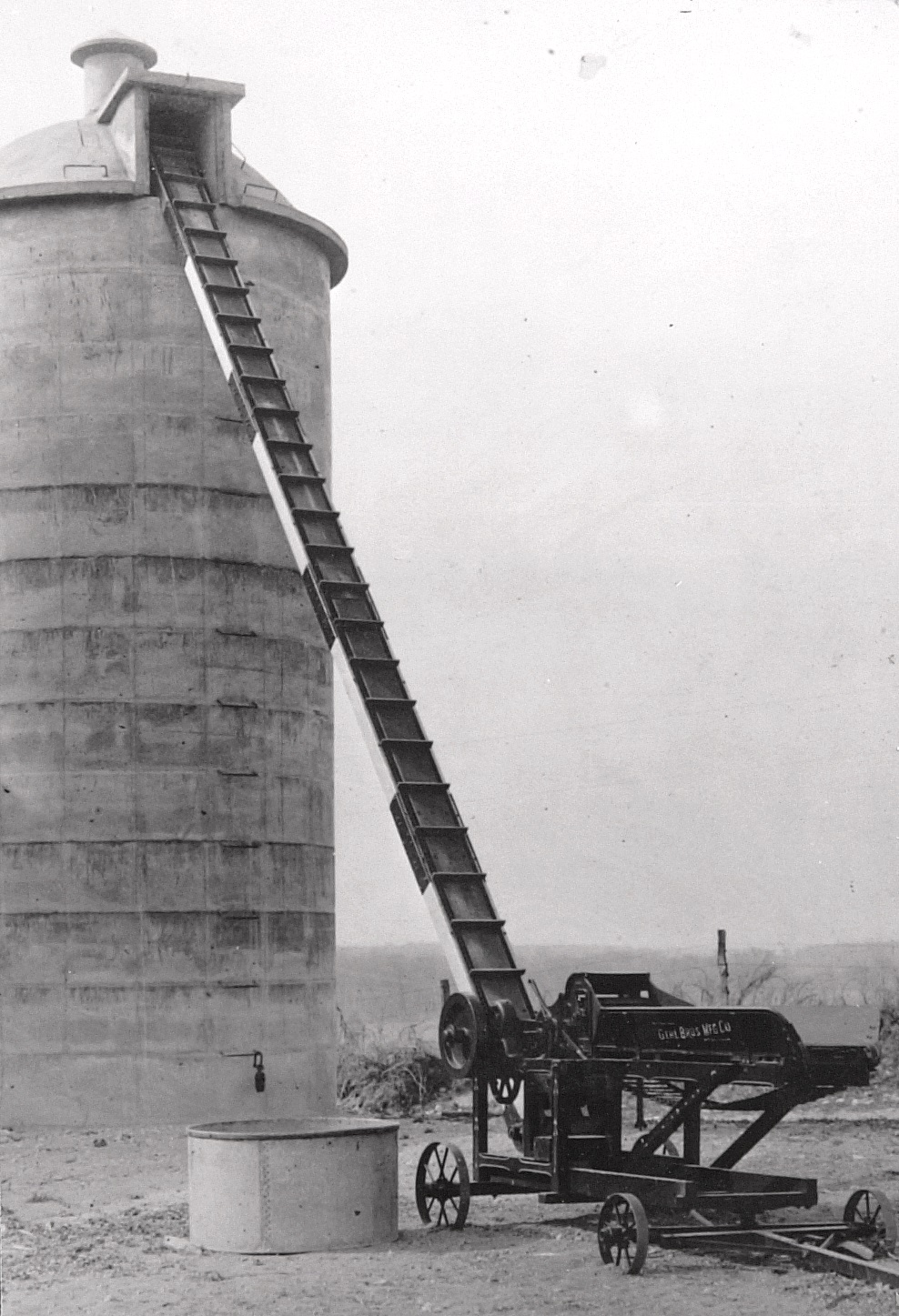

As for silo filling from that era, it may have been a conveyor setup on the silage cutter. Those would have been fairly low draft & easy enough to be powered by a horse power or sweep. There were also portable steam engines, steam traction engines & some electric motors early on that would have gotten the job done....

Or a blower type unit....

Mike

Here's a bit more on it from the Beloit Daily News, via the Wisconsin Historical Society site:

"Asymmetrically composed of three gabled bays projecting from a main block (with steeply pitched hip roof) and an octagonal tower at the southwest corner, the J.W. Crist House rises two stories plus attic from a foundation of rock-faced stone. The first and second stories are constructed of brick while the steeply-pitched gables have walls of fish-scale shingles. Gable returns, flared eaves, and a broad frieze ornament the cornice line of the house while each story of the three-story tower is marked by a stone string course. A modified Palladian window in the west gable features Iconic mullions, a molded panel in place of a fanlight and a classical frame with entablature, while other attic windows feature similar frames. The first floor entries and the side bay windows are ornamented with entablatures and doors are framed with pilasters and sidelights. Although the posts and roof of the veranda are now gone, the heavily rusticated stone foundation and walls of the veranda remains. Perhaps the most fanciful ornament is the brick work above the second story of the tower where diagonal rows of raised brick intersect each other to create a diamond pattern. Several additional farm buildings, including an elaborate concrete, brick, and steel dairy barn, built in the mid-20th century as part of the A.O. Smith operation, are located immediately behind the house but do not contribute to the significance of the house and are excluded from nomination. Once called the "Klondike Farmhouse" because its owner/builder had recently returned from the Alaska gold rush of 1896, the J.W. Crist House is architecturally significant as one of the finest Queen Anne houses in the city of Beloit, reflecting the tall proportions, varied massing, and freely interpreted classical detail which are hallmarks of the style. Probably designed by its owner, the Crist house was built as a farmhouse (then on the outskirts of Beloit), and remains today the finest example of a rural Queen Anne house now located in the city of Beloit. This large and imposing Queen Anne house, known as the "Klondike Farm," was built in 1904 by John W. Crist after he successfully mined gold in Alaska. But, if his fortune allowed him to build on a large scale, his background as a skilled carpenter helped him build as well. As a young man, crist worked as a carpenter for the Cunningham Brothers, a local contracting firm, before he moved west to Montana to build bridges for the Northern Pacific Railway. Eventually, Crist went to Alaska where he built a trading post in the Yukon Territory. During the great Klondike gold rush, Crist was reputed to have mined one of the first and richest mines in the territory. In 1901, Crist returned to Beloit, bought the rights to his family's farm, named the operation the "Klondike Farm." and began to build the large brick home which stands today. A strong promoter of rural interest, Crist served on the Rock County Board and other civic panels where he represented agricultural concerns. Throughout this period, the Klondike Farm was noted for its fine flock of sheep and its large herd of beef cattle, and the farm buildings that Crist built were considered among the finest in the county. But in 1914 fire destroyed many of thise buildings and Crist sold the property to W.J. Allen of Beloit who rebuilt the barns. By the early 1940s, the farm was owned by W.C. Heath, an executive with the A.O. Smith Corporation of Milwaukee, who built the present elaborate concrete, brick, and steel dairy barn that stands near the house. Mr. Heath also directed the buliding of one of the finest herds of purebred Brown Swiss cattle on the farm, and gave the place a new name - Swisstown. In 1947, the farm was bought by the A.O. Smith Corporation as a field research center. The corporation used the site for experimenting with such products as Harveststore crop storage units and dairying equipment. Eventually, A.O. Smith sold the property to Lester A. Helgesen of Janesville. Helgesen operated it for a number of years prior to selling it, and in recent years the farm has been partially subdivided. The area is becoming suburbanized, and the site has been annexed to the city."

The address is: 2601 Afton Rd., Beloit, Wi. 53511 if you would like to check it out on Maps.

Here's parts of a brochure I found on the 'net, with a pic of that silo (in B&W):

As for silo filling from that era, it may have been a conveyor setup on the silage cutter. Those would have been fairly low draft & easy enough to be powered by a horse power or sweep. There were also portable steam engines, steam traction engines & some electric motors early on that would have gotten the job done....

Or a blower type unit....

Mike

olgentdc

Well-known Member

They ;ve been making hot water tanks for 80 yrs or more ,,.. Burrowing in the bottom of a silo to make repairs still bugs Me ,,. I never did it ,, but I watched my Cousins do it ,,. In stalk silage it is relatively safe.. but ?The same A O Smith makes hot water tanks now!!

jus sayin

Similar threads

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy