Joel Sanderson

Member

I'm having some troubles:

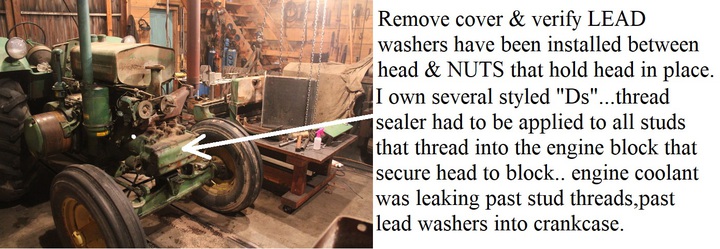

1) The fan on my '47 D came off while I was cutting wood and blew into the radiator. Ugh. I've taken it apart down to the fan shaft, and I see the fan shaft bearing is really loose--

possibly the cause of the problem. The service manual says the bearing can be removed after the dust cover is off, but how? There's a snap ring holding it in, but it doesn't have any

ears to pinch it together with snap ring liars. How do you get it out? Then, how do I get the bearing off the shaft without pulling the shaft out? The service manual doesn't say that's

necessary, and I'm hoping it's right.

2) I also seem to be missing one friction disc and washer. I don't know if it came off and went hop-skipping through the woods when the fan came off or not. Whatever, it's not there.

Anyone know where to get one? If not, I could make one if I had the dimensions. Is the front set exactly like the rear set?

3) The fan shaft's threads are stripped. It appears to have been 9/16 NF. Any reason why I can't take it down to 1/2-20 NF and just change nuts?

4) How does the overflow pipe fit into the top of the radiator? Whoever had this just glued a pipe into it. (Wow. I hope nothing else on this tractor is just glued together!) What keeps

it in? I see no picture of it in the service or parts manuals. It shows the connector, but nothing up inside.

Thanks for any help you have for me. This is my first time into this.

Joel

1) The fan on my '47 D came off while I was cutting wood and blew into the radiator. Ugh. I've taken it apart down to the fan shaft, and I see the fan shaft bearing is really loose--

possibly the cause of the problem. The service manual says the bearing can be removed after the dust cover is off, but how? There's a snap ring holding it in, but it doesn't have any

ears to pinch it together with snap ring liars. How do you get it out? Then, how do I get the bearing off the shaft without pulling the shaft out? The service manual doesn't say that's

necessary, and I'm hoping it's right.

2) I also seem to be missing one friction disc and washer. I don't know if it came off and went hop-skipping through the woods when the fan came off or not. Whatever, it's not there.

Anyone know where to get one? If not, I could make one if I had the dimensions. Is the front set exactly like the rear set?

3) The fan shaft's threads are stripped. It appears to have been 9/16 NF. Any reason why I can't take it down to 1/2-20 NF and just change nuts?

4) How does the overflow pipe fit into the top of the radiator? Whoever had this just glued a pipe into it. (Wow. I hope nothing else on this tractor is just glued together!) What keeps

it in? I see no picture of it in the service or parts manuals. It shows the connector, but nothing up inside.

Thanks for any help you have for me. This is my first time into this.

Joel