jon_schram

Member

Sorry for the long post...wife says I ramble.

So I have a Ferguson TO-30 (z129) tractor that we use around

the place for odd jobs. It's been in the family on-and-off since new. We actually put a ton of hours on it every year, as it is my wife's go-to for scraping manure, any road work that needs done, running roto-tiller, mowing, etc. The Hupp under/overdrive makes it the fastest tractor on the farm by a wide margin and it is awesome for running down the road to check cattle at the lease.

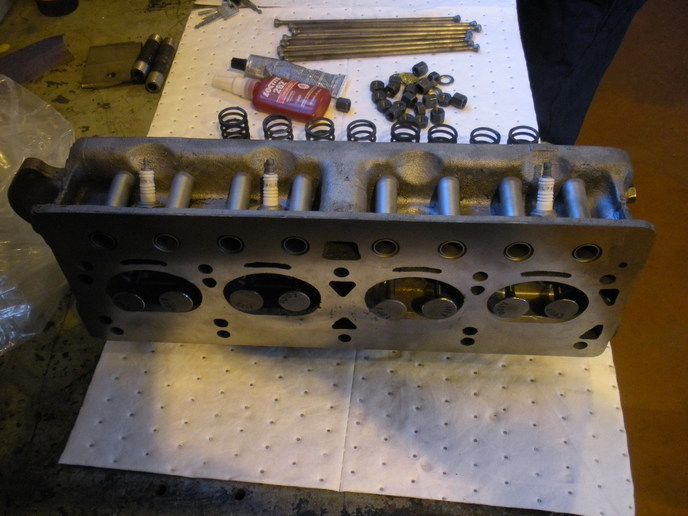

So, about a year ago it blew a head gasket while working it hard using a pto post hole digger. Since the compression was getting pretty low and the engine seemed tired, I went ahead and did an in-frame overhaul with new pistons, sleeves, etc. Also converted it over to electronic ignition at that time. Rebuild went great, and it was like having a new tractor for a time. I had an engine shop look over the head when I was doing the in-frame.

About 6 months ago the head gasket blew and we were getting oil into the radiator. No big deal, figured I got a bad gasket or neglected something during the rebuild. Threw a new head gasket in (properly torqued, etc) and went on our way.

Now I think I've blown the head gasket again. Getting coolant into the crank case. I know that z129's are prone to cracking, but I don't think that it ever got hot, and it was 50/50 antifreeze through the winter so I'm sure it didn't freeze.

Anybody had frequent head gasket problems in a Continental engine? Any advice, beyond just putting yet another head gasket in? Tractor runs great (besides the frequent head gaskets letting go), and is super handy around the farm for what we do.

I'm seriously considering dropping it off at a shop to have them work on it, but I'm afraid of what they will charge me to "diagnose" the problem and put yet another head gasket in that may or may not permanently solve the problem. I am also really considering putting in a can of head gasket gunk, but I've never had any luck with that crap.

Hopefully somebody here has an idea or advice that will keep me from having to tear into this thing every 6 months.

Thanks

So I have a Ferguson TO-30 (z129) tractor that we use around

the place for odd jobs. It's been in the family on-and-off since new. We actually put a ton of hours on it every year, as it is my wife's go-to for scraping manure, any road work that needs done, running roto-tiller, mowing, etc. The Hupp under/overdrive makes it the fastest tractor on the farm by a wide margin and it is awesome for running down the road to check cattle at the lease.

So, about a year ago it blew a head gasket while working it hard using a pto post hole digger. Since the compression was getting pretty low and the engine seemed tired, I went ahead and did an in-frame overhaul with new pistons, sleeves, etc. Also converted it over to electronic ignition at that time. Rebuild went great, and it was like having a new tractor for a time. I had an engine shop look over the head when I was doing the in-frame.

About 6 months ago the head gasket blew and we were getting oil into the radiator. No big deal, figured I got a bad gasket or neglected something during the rebuild. Threw a new head gasket in (properly torqued, etc) and went on our way.

Now I think I've blown the head gasket again. Getting coolant into the crank case. I know that z129's are prone to cracking, but I don't think that it ever got hot, and it was 50/50 antifreeze through the winter so I'm sure it didn't freeze.

Anybody had frequent head gasket problems in a Continental engine? Any advice, beyond just putting yet another head gasket in? Tractor runs great (besides the frequent head gaskets letting go), and is super handy around the farm for what we do.

I'm seriously considering dropping it off at a shop to have them work on it, but I'm afraid of what they will charge me to "diagnose" the problem and put yet another head gasket in that may or may not permanently solve the problem. I am also really considering putting in a can of head gasket gunk, but I've never had any luck with that crap.

Hopefully somebody here has an idea or advice that will keep me from having to tear into this thing every 6 months.

Thanks