My53Jubilee

Member

Hi all,

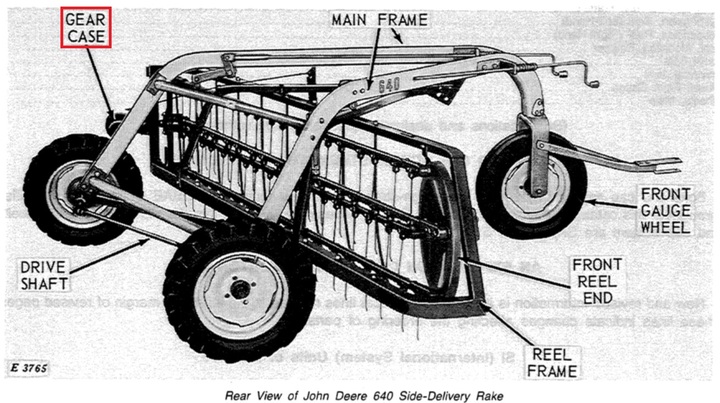

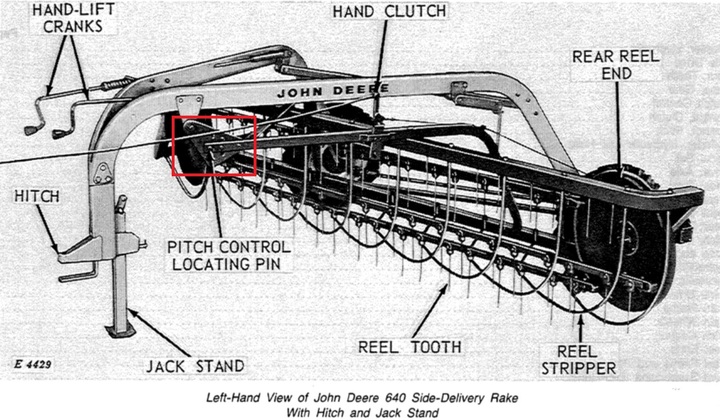

I recently purchased a John Deere Side delivery rake, and it has a plate on it, but no model number is listed. It only has a serial number.

The serial number is 111824E. The guy I bought it from says he thinks it is a 640. Can you help me verify what model of rake I have? I can post pictures if you need them, but wanted to start with the serial number.

Thanks!

I recently purchased a John Deere Side delivery rake, and it has a plate on it, but no model number is listed. It only has a serial number.

The serial number is 111824E. The guy I bought it from says he thinks it is a 640. Can you help me verify what model of rake I have? I can post pictures if you need them, but wanted to start with the serial number.

Thanks!