Ed S.

Well-known Member

- Location

- Middle Tennessee

Was just reading the thread on stick welders, which prompted me to "tap" into some of that knowledge for the workshop I'm building (and am now wiring) inside my big machine shed.

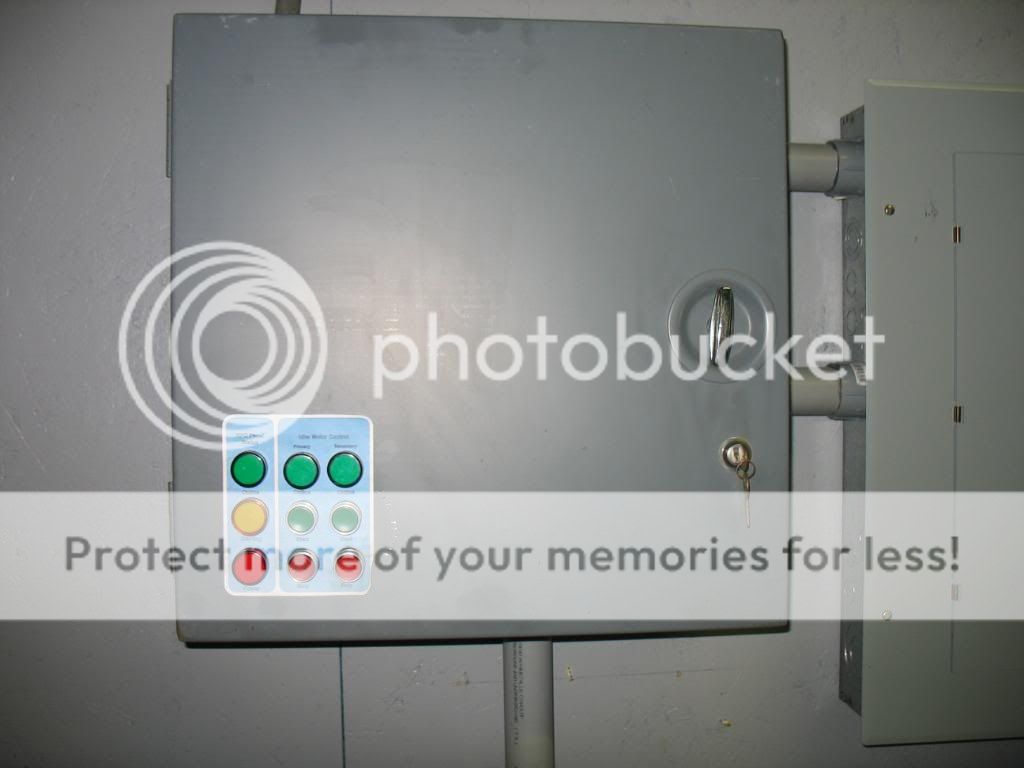

I have 3 phase to the barn, and have replaced the old 60 amp fuse box with a 100 amp panel. Would like to run two 220v lines, one for an eventual stick welder, and one for an eventual 60-80 gal. two-stage compressor.

First, I'm assuming I should use four-prong (grounded) outlets - I presume if I were to buy an older used welder, it would use the three-prong outlet, though?

And based on the other thread, it sounds like using at least a 50 amp breaker on the welder would be good... As I don't have the equipment yet, I can't read the tags or manuals to see what they would call for... maybe I should just pull the wire and wait to get the breaker?

Is there a "standard" breaker size for a 60-80 gal. two-stage compressor? Tech specs are scarce when googling, but I did see a couple that indicated a draw of around 30 amps (so I presume a 40 or 50 amp breaker?).

Lots of questions, not much detail, I know... just curious as the the general direction to take this while I'm still pulling wire.

So I guess the actual question is, "How would you wire yours if you were doing it anew?"

es

I have 3 phase to the barn, and have replaced the old 60 amp fuse box with a 100 amp panel. Would like to run two 220v lines, one for an eventual stick welder, and one for an eventual 60-80 gal. two-stage compressor.

First, I'm assuming I should use four-prong (grounded) outlets - I presume if I were to buy an older used welder, it would use the three-prong outlet, though?

And based on the other thread, it sounds like using at least a 50 amp breaker on the welder would be good... As I don't have the equipment yet, I can't read the tags or manuals to see what they would call for... maybe I should just pull the wire and wait to get the breaker?

Is there a "standard" breaker size for a 60-80 gal. two-stage compressor? Tech specs are scarce when googling, but I did see a couple that indicated a draw of around 30 amps (so I presume a 40 or 50 amp breaker?).

Lots of questions, not much detail, I know... just curious as the the general direction to take this while I'm still pulling wire.

So I guess the actual question is, "How would you wire yours if you were doing it anew?"

es