baldrick56

New User

Sorry for doing this one to death but I have a worsening problem with my TEA 20. In truth the problem started months ago on delivery of the tractor. Very slowly & tentatively reversing it off the trailer cos it was only my second time at the wheel and seemed to be like going backwards off a cliff onto the short ramps the trailer came with. Successfully unloaded there was a puddle of oil left at the back of the trailer deck but no more seemed to be coming out once it was on the flat.

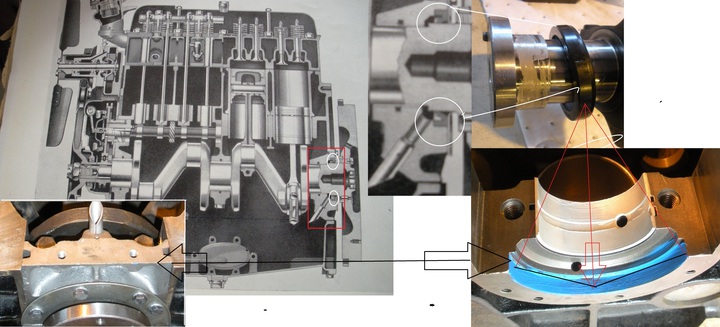

Yesterday I needed to use the tractor for some rock removal / tree trunk shifting duties. Over the course of a couple of hours it was running at all sorts of angles nose up, nose down, canted over Left, canted over Right & every combination in between. Had to stop when my wife pointed out the oil pouring out from under the bellhousing no longer just a drip but a steady trickle. Dipped the oil both ends to discover the source the transmission seemed not to have moved but the engine was on the middle mark of the stick (how come there s three marks? - at least on mine). Driving back to the parking area the oil pressure seemed lower than usual (still in the green but more to the left than previously). This morning I ve been doing a lot of reading on this & other forums amongst which the following from Bob:

quote "[i:89443533af]With all due respect, the REAR OIL SEAL is the worst Challenge you could have ever set out to do, let alone with the engine still attached to the forward components of Tractor.

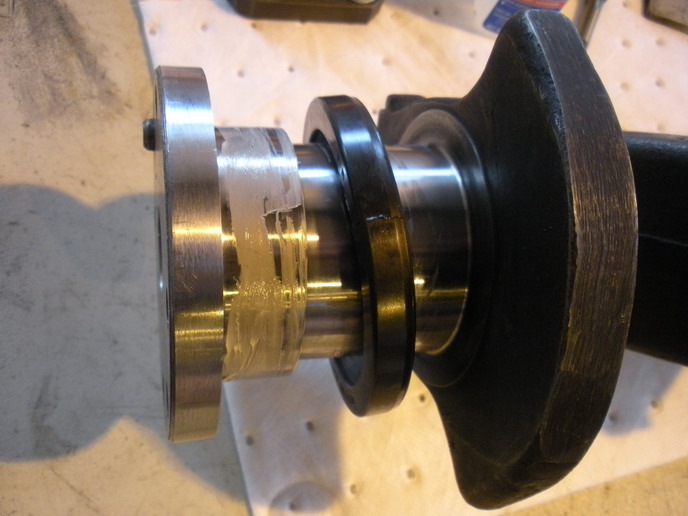

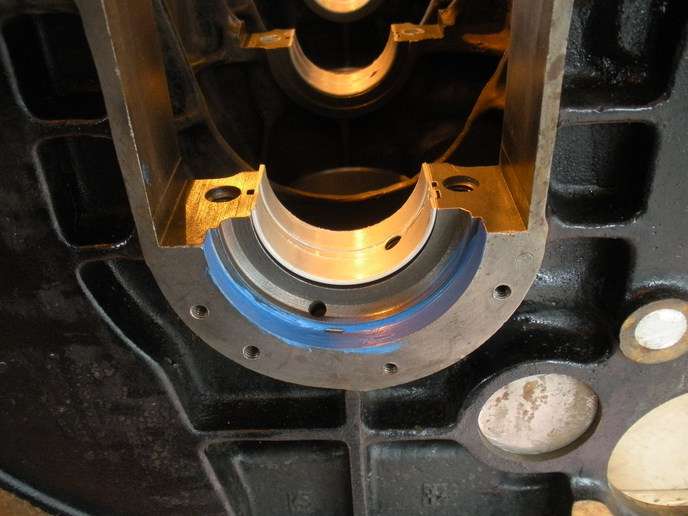

The Engine OIL should be drained, Oil Pan / Sump removed. Then at that time, the REAR BEARING BLOCK pulled away from the Engine block.

Working upside down trying to replace the rear Crank oil seal, I give you less that a 40% chance of a successful seal change out:[/i:89443533af]" quote

Now a word about the piece of paradise which the Fergie calls home its totally "off grid" no power, water, shed, hardstand, hardly any flat ground (Yup all those are on the "to do" list but none happened yet). All those pics I m looking at have people splitting the casing in nice comfy workshops or at least slabs what s wrong with people, don t they know a bit of hardship is good for the soul!

With all the above in mind my (cunning) plan is as follows:

1) buy two main seals plus one set of felt seals, plus pilot bearing, clutch release, and gearbox input seal;

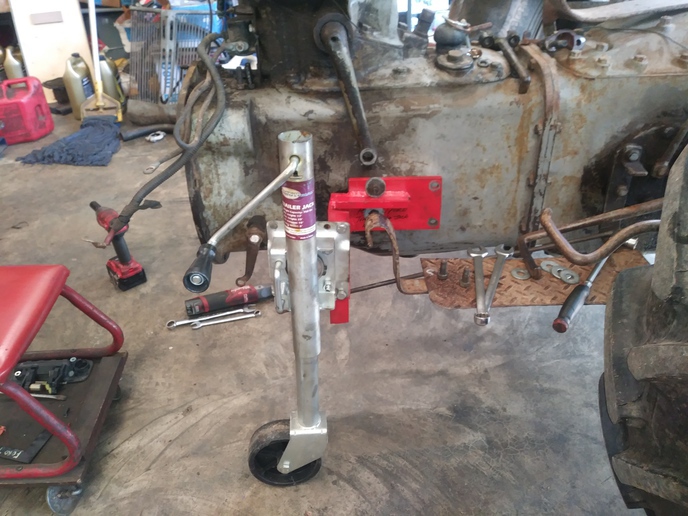

2) Split the case, chock the front axle against engine and roll front away from back;

3) Remove clutch & flywheel & replace main seal as outlined previously on this forum (ideally also coat the joints downstream of the felt seals with some kind of modern magic pliable penetrating sealing goo);

4) Lower rear end of engine to just above ground & look for leak when oil has flowed to back of sump;

5) If leak apparent then first new main seal is scrap & must attempt felt seal replacement with attendant 60% chance of failure;

6) If no leak raise engine, replace flywheel, clutch, pilot brg, clutch release, gearbox input seal (these last cos you don t have the case split like every weekend) oh and 2nd main seal / felt seals would be scrap but I think I d be more than happy with that!;

7) Re-unite front & back half of tractor;

Plan B would be to clear sufficient space at home (120kM away), rent a trailer, haul tractor back, do the job in workshop conditions with full dismantling & engine inversion, rent trailer again & haul back to farm. Probably add about $500 to total Bill (& lots of time as how many other faults & fix ups am I going to find with that level of dismantlement? :-/ ).

Choose wisely which is where I guess I m looking for guidance (oh and if anyone s got a suggestion for the magic goo to backstop the felt seal joint areas with?).

Yesterday I needed to use the tractor for some rock removal / tree trunk shifting duties. Over the course of a couple of hours it was running at all sorts of angles nose up, nose down, canted over Left, canted over Right & every combination in between. Had to stop when my wife pointed out the oil pouring out from under the bellhousing no longer just a drip but a steady trickle. Dipped the oil both ends to discover the source the transmission seemed not to have moved but the engine was on the middle mark of the stick (how come there s three marks? - at least on mine). Driving back to the parking area the oil pressure seemed lower than usual (still in the green but more to the left than previously). This morning I ve been doing a lot of reading on this & other forums amongst which the following from Bob:

quote "[i:89443533af]With all due respect, the REAR OIL SEAL is the worst Challenge you could have ever set out to do, let alone with the engine still attached to the forward components of Tractor.

The Engine OIL should be drained, Oil Pan / Sump removed. Then at that time, the REAR BEARING BLOCK pulled away from the Engine block.

Working upside down trying to replace the rear Crank oil seal, I give you less that a 40% chance of a successful seal change out:[/i:89443533af]" quote

Now a word about the piece of paradise which the Fergie calls home its totally "off grid" no power, water, shed, hardstand, hardly any flat ground (Yup all those are on the "to do" list but none happened yet). All those pics I m looking at have people splitting the casing in nice comfy workshops or at least slabs what s wrong with people, don t they know a bit of hardship is good for the soul!

With all the above in mind my (cunning) plan is as follows:

1) buy two main seals plus one set of felt seals, plus pilot bearing, clutch release, and gearbox input seal;

2) Split the case, chock the front axle against engine and roll front away from back;

3) Remove clutch & flywheel & replace main seal as outlined previously on this forum (ideally also coat the joints downstream of the felt seals with some kind of modern magic pliable penetrating sealing goo);

4) Lower rear end of engine to just above ground & look for leak when oil has flowed to back of sump;

5) If leak apparent then first new main seal is scrap & must attempt felt seal replacement with attendant 60% chance of failure;

6) If no leak raise engine, replace flywheel, clutch, pilot brg, clutch release, gearbox input seal (these last cos you don t have the case split like every weekend) oh and 2nd main seal / felt seals would be scrap but I think I d be more than happy with that!;

7) Re-unite front & back half of tractor;

Plan B would be to clear sufficient space at home (120kM away), rent a trailer, haul tractor back, do the job in workshop conditions with full dismantling & engine inversion, rent trailer again & haul back to farm. Probably add about $500 to total Bill (& lots of time as how many other faults & fix ups am I going to find with that level of dismantlement? :-/ ).

Choose wisely which is where I guess I m looking for guidance (oh and if anyone s got a suggestion for the magic goo to backstop the felt seal joint areas with?).