A few days ago I posted my opinion on oil change and what type and weight to use. I stated that I also use Lead-Substitute in my gas. Today there is another N owner asking about oil type. I stated in my previous post that I had knowledge of 2 motors that had their ND-oil replaced with Detergent oil and it resulted in plugged filters and pumps. I was told it was a myth, and even felt they thought I had made it up. I was also told that they have used nothing but Detergent oil in the crankcase and ATF as Lead-Substitute.I was also told Lead-Substitute was just petroleum distillant and was French for Diesel. So this week I spent a little time to research my fellow N owners replys to me. The oil myth is not a myth it is backed by facts. Almost all the tractor forums have some posters who have had problems with the change over to Detergent oil when it had been used in a motor that had had only Non-Detergent oil used previously. That said, it does not mean it will happen to every motor. I am sure there are a lot of variables involved. I also stated that after an overhaul use what you want. Lead-Substitute is something I use in my tractors and pickups made pryor to 1977. As far as it being just diesel fuel it is not. I use CD2, 1oz treats 10 gals and I also use Marvel oil, both cheaper then $4 a qt ATF and I doubt 1oz of ATF in 10 gals of gas could be much good or even detectable without a gascromatagraph. I found over 40 products with petroleum distillant listed as what they are so it is not just diesel however diesel can be used to stop engine ping at low altitudes. I got the backing of the following on my opinions

in these magazines, Farm Colletor and Gas Engines magazine. I have included a post from Yesterday's Tractors in this post and I invite everyone to read the 2 attchments of Yesterdays Tractor Articles. Again, I am only stating my opinion and what I have found in my research. I also found fourm posts that do not support my opinion as well.

Tuning Up Your Tractor (Part 3)

Oil, Oil Filter and Air Breather

by Curtis Von Fange

In the preceding articles we discussed some of the various aspects of doing a comprehensive tune up. Hopefully some light was shed on why we do or don't do certain things pertaining to inspections and order of events when doing a tune up. Perhaps some useful reasons were given for why parts fail and what to do about preventing part failure in the future. All these tips will help us think and reason out a problem in order to make our tune up last and, hopefully, keep us from spending extra money.

If the reader has been present from the beginning of this series he will recall making an inventory list before the tune up procedures began. On this list was a collection of observations of the overall engine and tractor condition. Some of the items on that list include the fluid levels and their color. As we continue our tune up discussion we will continue to examine some of the notes that were made.

The oil color can help you determine whether or not it is time for a change. On a gasoline engine, oil that is black as pitch is way beyond the change interval. Indications are that it is full of dissolved carbon and dirt. On the other hand, a diesel will usually have a black color to it as it is a reaction of the oil compounds and additives to the blow by of the piston which contains diesel fuel, sulphur, and emissions. A heavy brownish color of the oil along with tarnish on the dipstick usually indicates that the motor has been hot. The hot conditions have forced certain compounds of the oil to chemically react and produce the varnish looking appearance. A milky white color indicates excessive moisture in the engine. This can either result from a coolant leak into the oil or can be attributed to frequent on/off operation in colder or humid climates without letting the engine come up to a normal operating temperature for an extended period of time. Of course green droplets on the dipstick that smell sweet indicate antifreeze contamination in the crankcase. Oil that is an amber or lightish brown is the norm and should be changed along the recommended hourly or monthly guidelines supplied in your manual

A good tune up should include a fresh change of oil and filter. The oil is the blood of the motor. Microscopic oil films keeps moving metal parts from welding to each other. Keeping this lubricant clean and of a good quality will keep an engine running for many hours. There are many types of motor oils on the market today. Two basic catagories are the 'Texas' crudes and the 'Pennsylvania' crudes, each of which has their champions. Generally, the Texas crudes are pumped from deeper oil reservoirs and tend to have a higher parafinnic content than the Pennsylvania crudes. Since the oils have to meet a standard for parafin content it probably doesn't matter which geographic location it comes from. Oil viscosity is how fast the oil pours under given conditions. The lower the vis number the faster it flows. A 10 weight motor oil pours like milk at room temperature while a 40 weight pours like syrup. Lighter weights should be used under cold climate conditions where the motor will take a long time to come up to operating temperature; the lighter oil will lubricate better when cold. A heavier weight is best under hot climate or above normal engine running conditions as it won't run off of the motor parts as fast as a lighter oil. That is where multiviscosity oil, such as 10w-30, comes in. It has the characteristics of 10w oil when the engine first starts and the characteristics of 30w after operating temperature is reached. Some manufacturers recommend only a straight weight for their particular motor, so check your specs before you buy your oil.

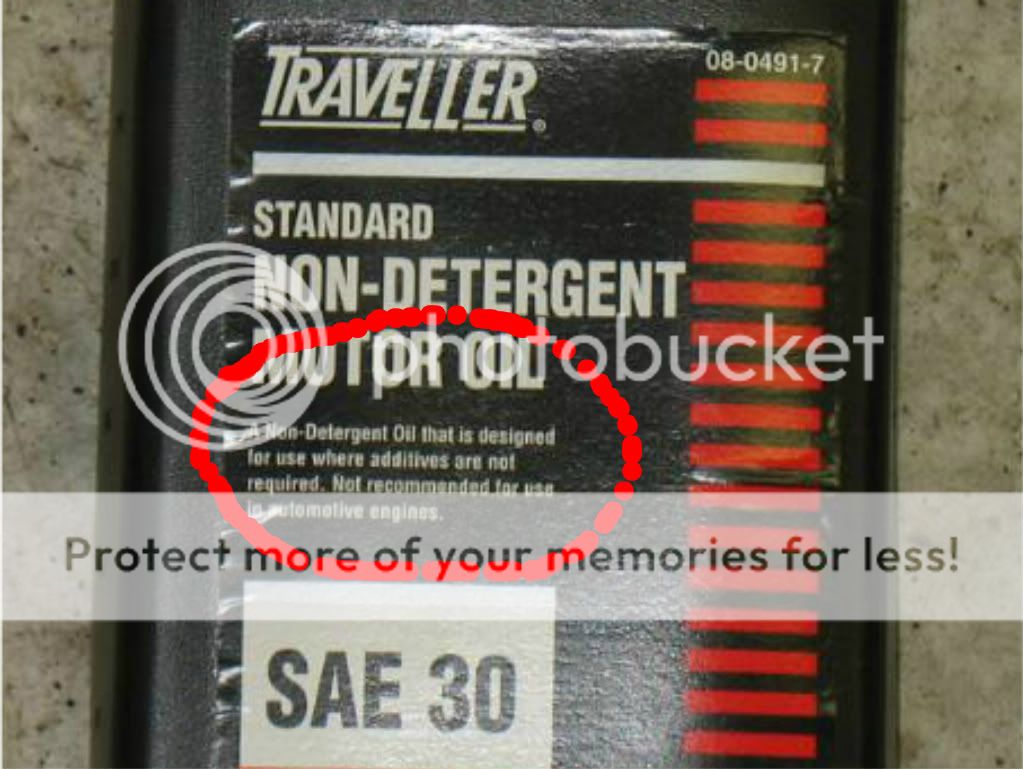

Another motor oil rating is the American Petroleum Institute or API rating. This rating, SA, SB, SC, or CA, CB, CC pertains to the application of the oil. The 'S' related numbers are referring to automobile useage, the 'C' rating is dealing with trucks, industrial, and diesel engine applications. The 'A' subheading refers to a light load application up to the 'C' subheading which is a more severe operation of the motor. The same applies for the 'C' main headings. Overall differences in the numbers pertain to the additives present in the oil which retard corrosion, sulphur content (as in diesels), particle suspension chemicals, moisture absorbability, oil shear, and the like. Check with your manual to determine the appropriate application for your engine. Some oils have a high detergent heading on their containers. Keep in mind that these oils have a high internal engine cleaning ability and may not be the best thing to put into an older, unrebuilt engine. These detergents can loosen up built up carbon, goo, and debris in an older unit that may cause more serious problems such as the plugging up of the oil intake screen or circulation galleys and filters. Non detergent oils are available and should be considered on older motors that have heavy deposit build ups under the valve covers or oil filler cap.

Bring the tractor up to operating temperature, shut it off, and drain the oil into a pan. If the tractor has a high oil pan you can put a wide mouth funnel into an old milk jug and drain it directly into your disposal container. Make sure that the jug is big enough to take all the crankcase has to offer, though. When the oil is drained clean the plug threads with a clean rag and reinstall the plug, then move your container underneath the oil filter. Remove it, place it upside down in your container or funnel and let the oil drain out. Wipe off any accumulated dirt around the seal where filter mates to the engine. If the filter is easy to get to and can be reinstalled without tipping, fill it with clean motor oil before replacing it. Remove the engine breather cap or oil filler cap and inspect its underside. It should be generally clean of carbon, dirt, and goo. Heavy buildup or concentrations of the above may indicate further ventilation problems in the motor vapor circuit. Check the PCV (positive crankcase ventilation) valve and make sure it freely rattles and does not bind from excessive moisture/oil buildup. You also might check any vacuum hoses to the carburator base making sure they are not collapsed or have pin holes in them. Clean the oil cap and PCV valve with clean solvent, blow dry and reinstall. Fill the motor with the correct type and amount of oil. Do not overfill as the extra oil may cavitate in crankcase as the crankshaft counterweights come around. It will also promote seal and gasket failure by submerging those items in a constant bath of oil. One last note is to take the oil and filter to a recycling center for proper disposal. Consider that the oil itself never wears out, it merely gets dirty and the additives wear out. By re-refining it the oil will be identical to the stuff that comes out of the ground and goes through the same refining process.

After the oil and oil filter are replaced take a moment to inspect the air cleaner or oil bath unit. This often overlooked step may, literally, breath new life into your engine. If the filters have excessive dirt and debris in them it will reduce the efficiency of your engine by enriching the fuel to the combustion chamber. This will result in poor performance, black exhaust, excessive carbon buildup, washing of the cylinder walls from too much fuel, and internal engine wear. If the unit has a paper filter, remove it and inspect it for squashing or torn paper in the element itself along with any evidence of oil. If sound, reverse blow it (from inside to out) with an air gun taking care not to get too close to the paper itself with the air stream. Clean out the filter cannister, check the cannister to carburator gasket, and reinstall with the correct torque on the wingnut or retaining fastener. Oil in the filter element can indicate a faulty ventilation system or excessive blow by of the pistons from worn or broken rings. If the tractor has an oil bath cleaner assembly then remove the unit and disassemble on a work bench. Lift out the wire mesh and clean it in mineral spirits or equivalent solvent and let it air dry. Dispose of the oil in the lower body assembly, clean out the cannister bottom, and refill with fresh oil to the fill line. Check the tube that the air flows through to the engine (if so equiped) for dirt build up and debris. Also check the oil bath air cap assembly (if so equiped) for weed seeds and dirt. This unit is designed to make the incoming air create a vortex which moves much of the heavier material to the outside of the breather cap through centifugal force. The heavier debris then settles along the outside rim of the cap or dust collector instead of going into the oil bath itself. Before closing the cowl on the air breather service, check any intake air hoses between the engine and filter for cracking, drying out, oil contamination, or pin holes. In a dusty field even the smallest hole can let in damaging dirt.

Our engine should now have clean air and oil to extend it's life span and give it the ability to perform at its peak. Our topic next time will cover the cooling and fuel system along with miscellaneous tips on diagnosing engine maladies.

Product Review

Lead Substitutes

by Mike Schordine

Lead was originally added to gasoline as an upper cylinder lubricant. It lubes the valves and seats. If you rebuild the motor, you could use hardened seats and valves, and unleaded fuel.

But if your old tractor runs good, a simple lead substitute added to the gas is a perfectly reasonable solution. And, if you are like me, your tractor is under cover, but it sits outside. So with every temperature change, the humidity in the air collects in the fuel tank, in the form of water.

Now you need a moisture management protocol. Does this mean that you need to buy a bunch of additives? No! There is a product that I’ve been using for the last 10 years. It is a lead substitute, a moisture management package, and an octane booster!! It works so well that I became a distributor for the manufacturer.

It is called Maxi-Mizer. It’s made in this country, originally for the space shuttle program. The catalyst in it makes the fuel burn more completely and results in better fuel endurance. It burns the fuel in the motor, that would normally exit as unburnt hydrocarbons.

You could buy a lot of additives and still not get all the benefits of this one product.

When used with Maxi-Mizer MBL, the extreme pressure motor oil additive which reduces friction, the benefits are compounded. The extreme pressure lube can be added to the transmission, rear axle, and hydraulic system with similiar benefits.

These products are called the performance set, and have been used by the racing profession for years. Maxi-Mizer comes in gas and diesel formulas. For $22.00, one 16 oz. bottle treats 320 gallons of gasoline, and with all of its qualities, the choice of which additive to use is clear.

These products can be purchased from me, and your Farm Tax Exemptions are welcome. For more information and to purchase these products, please call Mike Schordine at (516) 924-2875; or e-mail at [email protected]. You can also write to:

Schordine Refrigeration, Inc.

134 Waverly Ave.

Patchogue, NY 11772

in these magazines, Farm Colletor and Gas Engines magazine. I have included a post from Yesterday's Tractors in this post and I invite everyone to read the 2 attchments of Yesterdays Tractor Articles. Again, I am only stating my opinion and what I have found in my research. I also found fourm posts that do not support my opinion as well.

Tuning Up Your Tractor (Part 3)

Oil, Oil Filter and Air Breather

by Curtis Von Fange

In the preceding articles we discussed some of the various aspects of doing a comprehensive tune up. Hopefully some light was shed on why we do or don't do certain things pertaining to inspections and order of events when doing a tune up. Perhaps some useful reasons were given for why parts fail and what to do about preventing part failure in the future. All these tips will help us think and reason out a problem in order to make our tune up last and, hopefully, keep us from spending extra money.

If the reader has been present from the beginning of this series he will recall making an inventory list before the tune up procedures began. On this list was a collection of observations of the overall engine and tractor condition. Some of the items on that list include the fluid levels and their color. As we continue our tune up discussion we will continue to examine some of the notes that were made.

The oil color can help you determine whether or not it is time for a change. On a gasoline engine, oil that is black as pitch is way beyond the change interval. Indications are that it is full of dissolved carbon and dirt. On the other hand, a diesel will usually have a black color to it as it is a reaction of the oil compounds and additives to the blow by of the piston which contains diesel fuel, sulphur, and emissions. A heavy brownish color of the oil along with tarnish on the dipstick usually indicates that the motor has been hot. The hot conditions have forced certain compounds of the oil to chemically react and produce the varnish looking appearance. A milky white color indicates excessive moisture in the engine. This can either result from a coolant leak into the oil or can be attributed to frequent on/off operation in colder or humid climates without letting the engine come up to a normal operating temperature for an extended period of time. Of course green droplets on the dipstick that smell sweet indicate antifreeze contamination in the crankcase. Oil that is an amber or lightish brown is the norm and should be changed along the recommended hourly or monthly guidelines supplied in your manual

A good tune up should include a fresh change of oil and filter. The oil is the blood of the motor. Microscopic oil films keeps moving metal parts from welding to each other. Keeping this lubricant clean and of a good quality will keep an engine running for many hours. There are many types of motor oils on the market today. Two basic catagories are the 'Texas' crudes and the 'Pennsylvania' crudes, each of which has their champions. Generally, the Texas crudes are pumped from deeper oil reservoirs and tend to have a higher parafinnic content than the Pennsylvania crudes. Since the oils have to meet a standard for parafin content it probably doesn't matter which geographic location it comes from. Oil viscosity is how fast the oil pours under given conditions. The lower the vis number the faster it flows. A 10 weight motor oil pours like milk at room temperature while a 40 weight pours like syrup. Lighter weights should be used under cold climate conditions where the motor will take a long time to come up to operating temperature; the lighter oil will lubricate better when cold. A heavier weight is best under hot climate or above normal engine running conditions as it won't run off of the motor parts as fast as a lighter oil. That is where multiviscosity oil, such as 10w-30, comes in. It has the characteristics of 10w oil when the engine first starts and the characteristics of 30w after operating temperature is reached. Some manufacturers recommend only a straight weight for their particular motor, so check your specs before you buy your oil.

Another motor oil rating is the American Petroleum Institute or API rating. This rating, SA, SB, SC, or CA, CB, CC pertains to the application of the oil. The 'S' related numbers are referring to automobile useage, the 'C' rating is dealing with trucks, industrial, and diesel engine applications. The 'A' subheading refers to a light load application up to the 'C' subheading which is a more severe operation of the motor. The same applies for the 'C' main headings. Overall differences in the numbers pertain to the additives present in the oil which retard corrosion, sulphur content (as in diesels), particle suspension chemicals, moisture absorbability, oil shear, and the like. Check with your manual to determine the appropriate application for your engine. Some oils have a high detergent heading on their containers. Keep in mind that these oils have a high internal engine cleaning ability and may not be the best thing to put into an older, unrebuilt engine. These detergents can loosen up built up carbon, goo, and debris in an older unit that may cause more serious problems such as the plugging up of the oil intake screen or circulation galleys and filters. Non detergent oils are available and should be considered on older motors that have heavy deposit build ups under the valve covers or oil filler cap.

Bring the tractor up to operating temperature, shut it off, and drain the oil into a pan. If the tractor has a high oil pan you can put a wide mouth funnel into an old milk jug and drain it directly into your disposal container. Make sure that the jug is big enough to take all the crankcase has to offer, though. When the oil is drained clean the plug threads with a clean rag and reinstall the plug, then move your container underneath the oil filter. Remove it, place it upside down in your container or funnel and let the oil drain out. Wipe off any accumulated dirt around the seal where filter mates to the engine. If the filter is easy to get to and can be reinstalled without tipping, fill it with clean motor oil before replacing it. Remove the engine breather cap or oil filler cap and inspect its underside. It should be generally clean of carbon, dirt, and goo. Heavy buildup or concentrations of the above may indicate further ventilation problems in the motor vapor circuit. Check the PCV (positive crankcase ventilation) valve and make sure it freely rattles and does not bind from excessive moisture/oil buildup. You also might check any vacuum hoses to the carburator base making sure they are not collapsed or have pin holes in them. Clean the oil cap and PCV valve with clean solvent, blow dry and reinstall. Fill the motor with the correct type and amount of oil. Do not overfill as the extra oil may cavitate in crankcase as the crankshaft counterweights come around. It will also promote seal and gasket failure by submerging those items in a constant bath of oil. One last note is to take the oil and filter to a recycling center for proper disposal. Consider that the oil itself never wears out, it merely gets dirty and the additives wear out. By re-refining it the oil will be identical to the stuff that comes out of the ground and goes through the same refining process.

After the oil and oil filter are replaced take a moment to inspect the air cleaner or oil bath unit. This often overlooked step may, literally, breath new life into your engine. If the filters have excessive dirt and debris in them it will reduce the efficiency of your engine by enriching the fuel to the combustion chamber. This will result in poor performance, black exhaust, excessive carbon buildup, washing of the cylinder walls from too much fuel, and internal engine wear. If the unit has a paper filter, remove it and inspect it for squashing or torn paper in the element itself along with any evidence of oil. If sound, reverse blow it (from inside to out) with an air gun taking care not to get too close to the paper itself with the air stream. Clean out the filter cannister, check the cannister to carburator gasket, and reinstall with the correct torque on the wingnut or retaining fastener. Oil in the filter element can indicate a faulty ventilation system or excessive blow by of the pistons from worn or broken rings. If the tractor has an oil bath cleaner assembly then remove the unit and disassemble on a work bench. Lift out the wire mesh and clean it in mineral spirits or equivalent solvent and let it air dry. Dispose of the oil in the lower body assembly, clean out the cannister bottom, and refill with fresh oil to the fill line. Check the tube that the air flows through to the engine (if so equiped) for dirt build up and debris. Also check the oil bath air cap assembly (if so equiped) for weed seeds and dirt. This unit is designed to make the incoming air create a vortex which moves much of the heavier material to the outside of the breather cap through centifugal force. The heavier debris then settles along the outside rim of the cap or dust collector instead of going into the oil bath itself. Before closing the cowl on the air breather service, check any intake air hoses between the engine and filter for cracking, drying out, oil contamination, or pin holes. In a dusty field even the smallest hole can let in damaging dirt.

Our engine should now have clean air and oil to extend it's life span and give it the ability to perform at its peak. Our topic next time will cover the cooling and fuel system along with miscellaneous tips on diagnosing engine maladies.

Product Review

Lead Substitutes

by Mike Schordine

Lead was originally added to gasoline as an upper cylinder lubricant. It lubes the valves and seats. If you rebuild the motor, you could use hardened seats and valves, and unleaded fuel.

But if your old tractor runs good, a simple lead substitute added to the gas is a perfectly reasonable solution. And, if you are like me, your tractor is under cover, but it sits outside. So with every temperature change, the humidity in the air collects in the fuel tank, in the form of water.

Now you need a moisture management protocol. Does this mean that you need to buy a bunch of additives? No! There is a product that I’ve been using for the last 10 years. It is a lead substitute, a moisture management package, and an octane booster!! It works so well that I became a distributor for the manufacturer.

It is called Maxi-Mizer. It’s made in this country, originally for the space shuttle program. The catalyst in it makes the fuel burn more completely and results in better fuel endurance. It burns the fuel in the motor, that would normally exit as unburnt hydrocarbons.

You could buy a lot of additives and still not get all the benefits of this one product.

When used with Maxi-Mizer MBL, the extreme pressure motor oil additive which reduces friction, the benefits are compounded. The extreme pressure lube can be added to the transmission, rear axle, and hydraulic system with similiar benefits.

These products are called the performance set, and have been used by the racing profession for years. Maxi-Mizer comes in gas and diesel formulas. For $22.00, one 16 oz. bottle treats 320 gallons of gasoline, and with all of its qualities, the choice of which additive to use is clear.

These products can be purchased from me, and your Farm Tax Exemptions are welcome. For more information and to purchase these products, please call Mike Schordine at (516) 924-2875; or e-mail at [email protected]. You can also write to:

Schordine Refrigeration, Inc.

134 Waverly Ave.

Patchogue, NY 11772