Hello all!

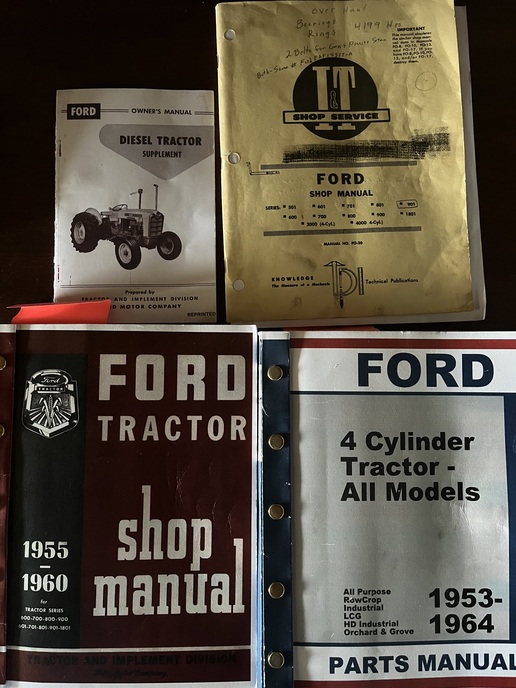

This looks like the place to be to learn about old tractors! I type slow and have too much to do so I'll keep it short for now. About a year ago we bought a old dilapidated farm on 9.25 acres in North Central Florida. We're renovating the house and the property with the goal of providing comfortable shelter and the ability to produce some food. I recently bought a '61 841 Powermaster, my first tractor and it's the same vintage as me! I'm a life long hotrodder, mechanic and general fix it guy. So far have a brush hog, a box blade and a boom lift for implements. I'm sure that I'll have many more questions and hopefully some time for socializing in the future. But for now my first questions is there a more modern upgrade for the oil bath air filter? Maybe something that retains the look of the original part with a modern element inside? Since I'm wet behind the ears in regards to tractors, I'll ask what's normally considered a safe sustained operating RPM? The same for water temperature?

TIA and happy to have found this place!

Best,

Rich in Archer

This looks like the place to be to learn about old tractors! I type slow and have too much to do so I'll keep it short for now. About a year ago we bought a old dilapidated farm on 9.25 acres in North Central Florida. We're renovating the house and the property with the goal of providing comfortable shelter and the ability to produce some food. I recently bought a '61 841 Powermaster, my first tractor and it's the same vintage as me! I'm a life long hotrodder, mechanic and general fix it guy. So far have a brush hog, a box blade and a boom lift for implements. I'm sure that I'll have many more questions and hopefully some time for socializing in the future. But for now my first questions is there a more modern upgrade for the oil bath air filter? Maybe something that retains the look of the original part with a modern element inside? Since I'm wet behind the ears in regards to tractors, I'll ask what's normally considered a safe sustained operating RPM? The same for water temperature?

TIA and happy to have found this place!

Best,

Rich in Archer