Zachary Hoyt

Well-known Member

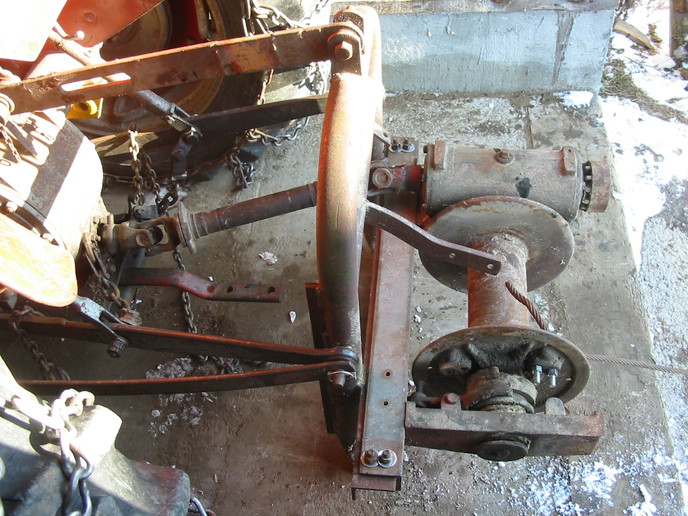

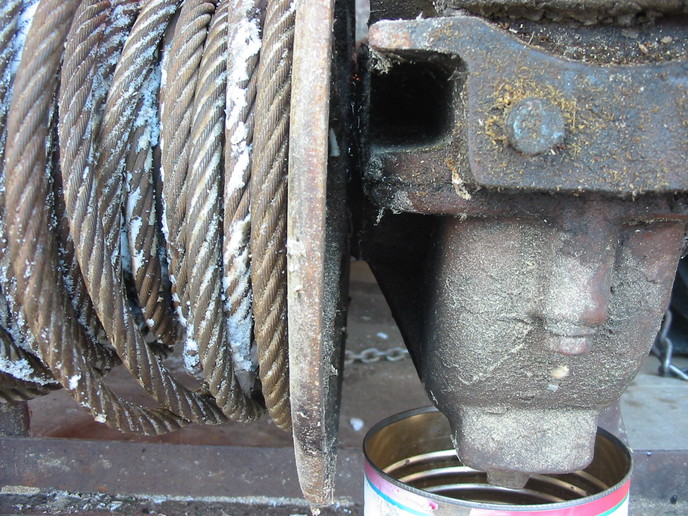

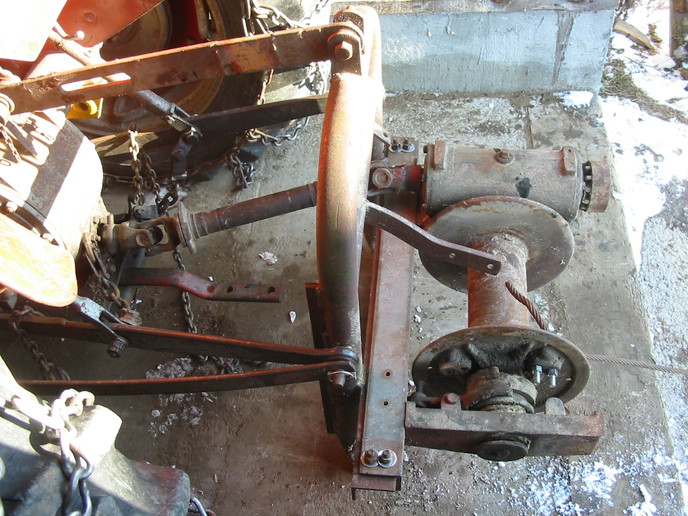

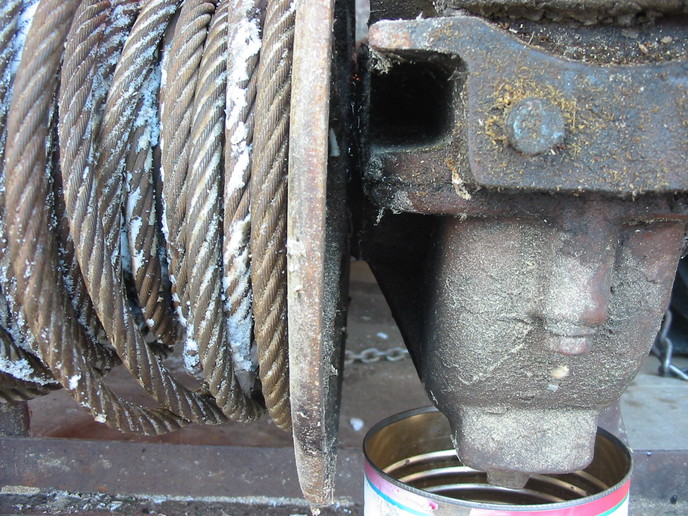

I finally got myself together and bolted the winch up to the frame and hooked it to the tractor. I then filled the gear box with 80-90, ran the winch briefly to see that it was working and got out the cable. The top photo shows how long the cable is, before I ran it onto the drum. As I was watching it winding the gear oil began to leak from both sides of the gearbox where the drum shaft comes out. I am wondering if I should take it apart and replace the seals or put in flowable grease that I have heard about on here or look for one of those 'miracle' products that swell rubber and stop leaks. If the correct answer is A, which I suspect, could anyone tell me if there is a place I could find a parts diagram or other information about how to take it apart? I am hoping that I can get seals through NAPA, or our local industrial supply house. The drum has the letters GW inside a circle, which I imagine may be the manufacturers mark. Any advice will be much appreciated.

Zach

Zach